For decades, the most common way to to keep the water out and maintain a building’s rigid air barrier was by dressing any pipes or ducting that penetrated the exterior cladding with tape. This method of cavity flashing depended entirely upon the skill of the person installing it and was prone to failure over time.

That’s because, John Lukaszewicz of Vanluk says, often the tape would come into contact with sealant, which caused a reaction and meant the sealant would fail over time, breaking the rigid air barrier and allowing air, and moisture, to enter a building, or that pipe or cable was pulled (after tape dressing) compromising the installation.

Weather tightness with quick and easy installation

“It was because of this common failure that we designed a different style of cavity flashing that relies less on the skill of the installer, and can be installed quickly and easily on site,” John says. “They can also be pre‐profiled to any shape or size. The purpose of developing this product was to maintain a building’s rigid air barrier over time and allow for a quick and easy installation.”

The new cavity flashings were first introduced to the market nearly a decade ago and have had a remarkable effect on the industry. John says following Vanluk’s launch of this product, the market has come up with various similar alternative cavity flashing systems – something he says is great for the building industry.

Essentially, it has forced people to recognise that there is a requirement for something like this. Now, it’s much rarer for people to just put a penetration through a building and dress tape around it.

Tape’s on the out

While it’s a requirement of the Building Code to have some form of cavity flashing, it is still acceptable to use tape for this purpose, but because of the ease and effectiveness of the new technology, the market has itself reduced the commonality of this method.

One sizes does not have to fit all

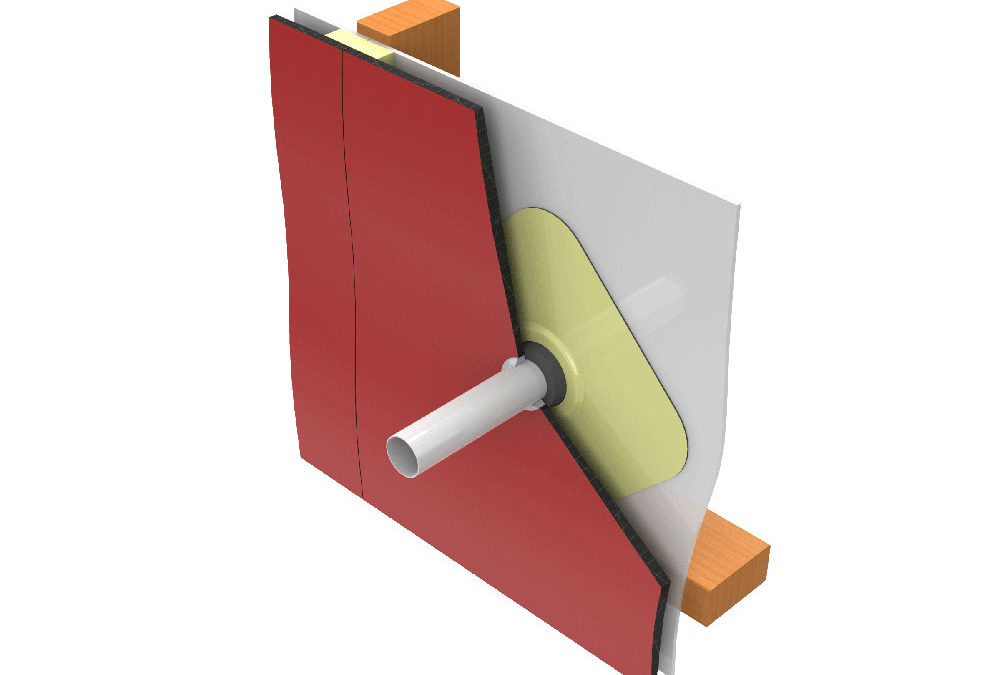

Vanluk’s cavity flashings are available in two ranges, the MG‐100 pipe and cable cavity flashing, which is designed for bigger penetrations, and the MG‐50 pipe and cable cavity flashing. The latter comes in one size, but the hole can be dye cut to the precise size required by the client. It is made of injection‐moulded thermoprene rubber.

The larger sized MG‐100 range cavity flashings are made of EVA foam, and like the smaller range, are backed with reinforced butyl rubber. This range can be made to fit any size and dye cut to any required shape. This style of cavity flashing should be used on all downpipes, waterpipes and waste pipes that run through the cladding face.

Weather tightness is not an additional extra

The Vanluk cavity flashings are an inexpensive addition to a property that will protect the building in the critical areas. They’re a vital part of construction because these areas are the places where buildings can and do fail.

The ranges are being used across the board in applications from commercial settings through to residential homes. On a residential property, you could be looking at needing anywhere from one to 10, for example, while in commercial properties they can be used for all sorts of purposes. Recently, for example, we supplied 84 for a bank’s signage, and thousands for a large shopping mall.

Vanluk’s cavity flashings are custom‐made in New Zealand. There is always a standard range of both sizes in stock, but custom-made pieces can be manufactured with short lead times.

If you would like more information about our flashing solutions, please download our brochure or send us an email.